We at UAShelters.com are dedicated to providing ready-made modular protective shelters to ensure the safety and well-being of the population in Ukraine.

Our team consists of experienced professionals in the construction industry with a solid commitment to quality and safety.

In light of the recent events involving Russia’s invasion of Ukraine, we have intensified our efforts to implement protective shelter projects, understanding the paramount importance of preserving human life.

Our guiding principle is “PROTECTING SAFETY.” We believe that investing in security leads to peace of mind, future development, and protecting one’s employees and loved ones.

While we have already successfully completed protective shelter projects at critical infrastructure facilities, we are unable to disclose all the details due to security restrictions. However, we are more than willing to share information about our shelters, including certifications, components, and accessories, upon request.

The UAShelters.com team is ready to provide as much information as possible about our SHELTERS (certificates of conformity, ISO, what components and accessories the product consists of, etc.).

We are open to collaborating with manufacturers, sellers of protective shelters, as well as companies supplying components for electrical installation, ventilation equipment, and building materials. Please feel free to reach out to us for further information or collaboration opportunities.

If you have any questions or need further assistance, please don’t hesitate to ask.

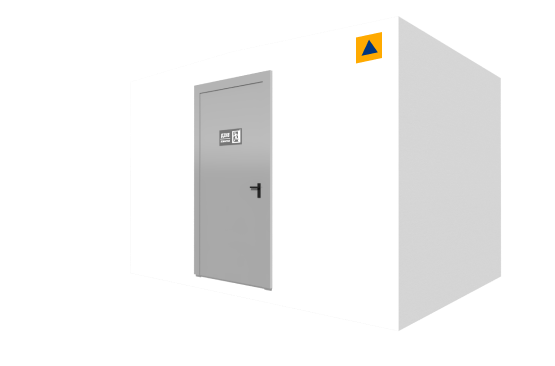

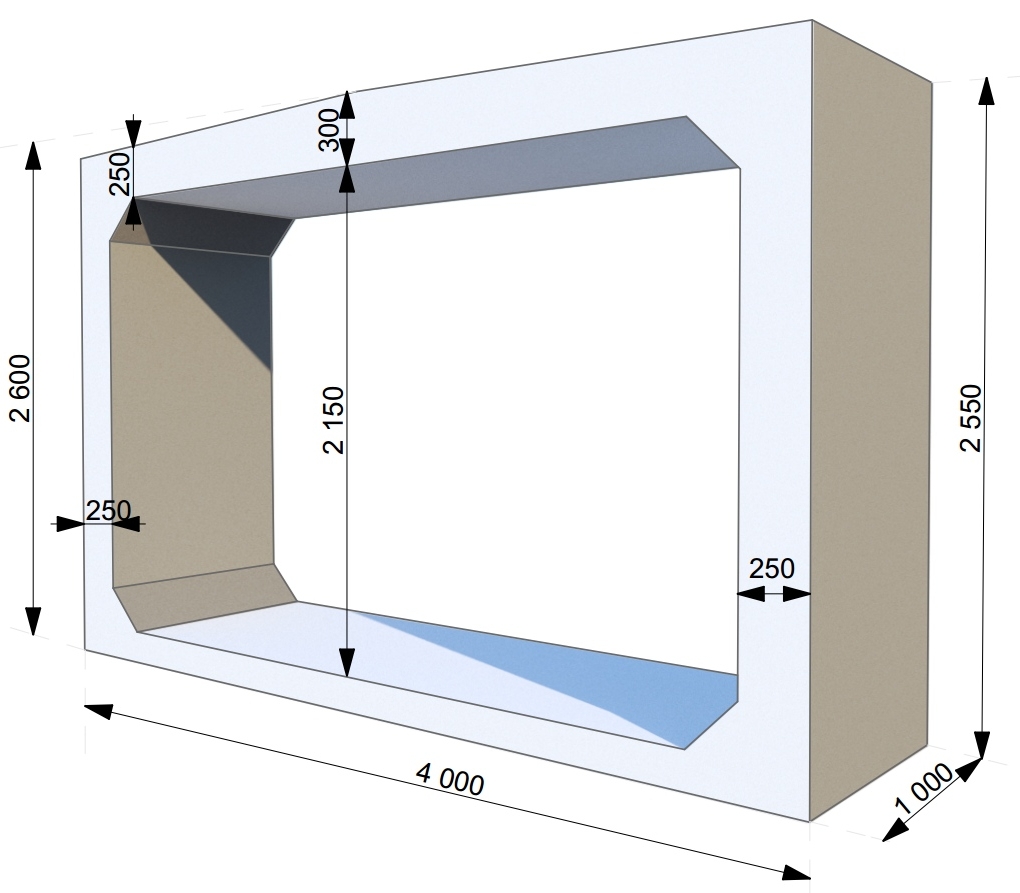

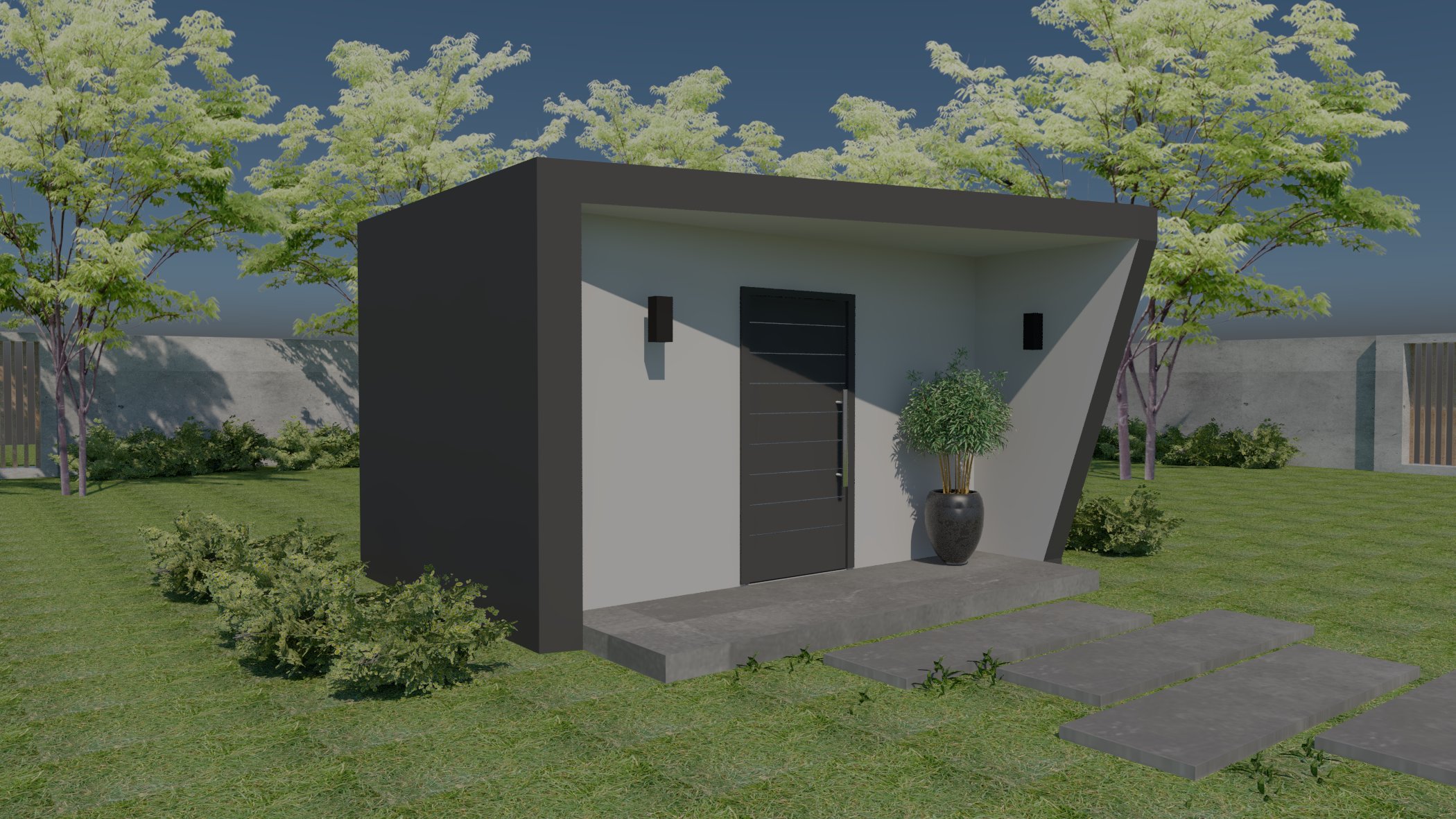

Modular protective civil defense shelter OBERIG.

This is a modular reinforced concrete product that fully complies with DSTU 9195:2022. It consists of separate units (modules) that are interconnected to form a specialized structure designed to protect people. According to DBN B.2.2-5:2023 (Annex B), in new construction, the design area for one adult is from 0.5 to 1.1 m2 and for a child from 1.2 to 3 m2, depending on the type and capacity of the shelter.

Preparing the site for installation of the fire protection system.

Installing units using technological fasteners on the prepared concrete surface.

Fixing units and end plates to each other by welding embedded elements and metal reinforcing plates.

Our shelters boast key elements that are manufactured to the highest standards. The main modules and end plates are produced in accordance with the stringent requirements of DSTU 9195-2022 and DBN B.2.2-5:2023.

The manufacturing process of units strictly adheres to the specifications outlined in DCTU B B.2.6-2:2009 for concrete and reinforced concrete structures.

Main modules and end plates are cast using heavy C32/40-grade concrete according to DSTU B V.2.7-96-2000, employing unified molds for reinforced concrete structures (RCS). Each mold is pre-fitted with a multilayer reinforcing frame made of A500C rebar of DSTU 3760:2006 class with 12mm to 14mm thickness, along with an additional steel anti-shatter mesh with a 2mm bar thickness. The pouring process is meticulously executed using vibrating probes to guarantee superior compaction of the concrete solution.

The duration of the process, from pouring to hardening and readiness of the units for use, takes more than 21 days.

Each module (unit) weighs up to 6.5 tons,

While the end plate weighs up to 4.5 tons.

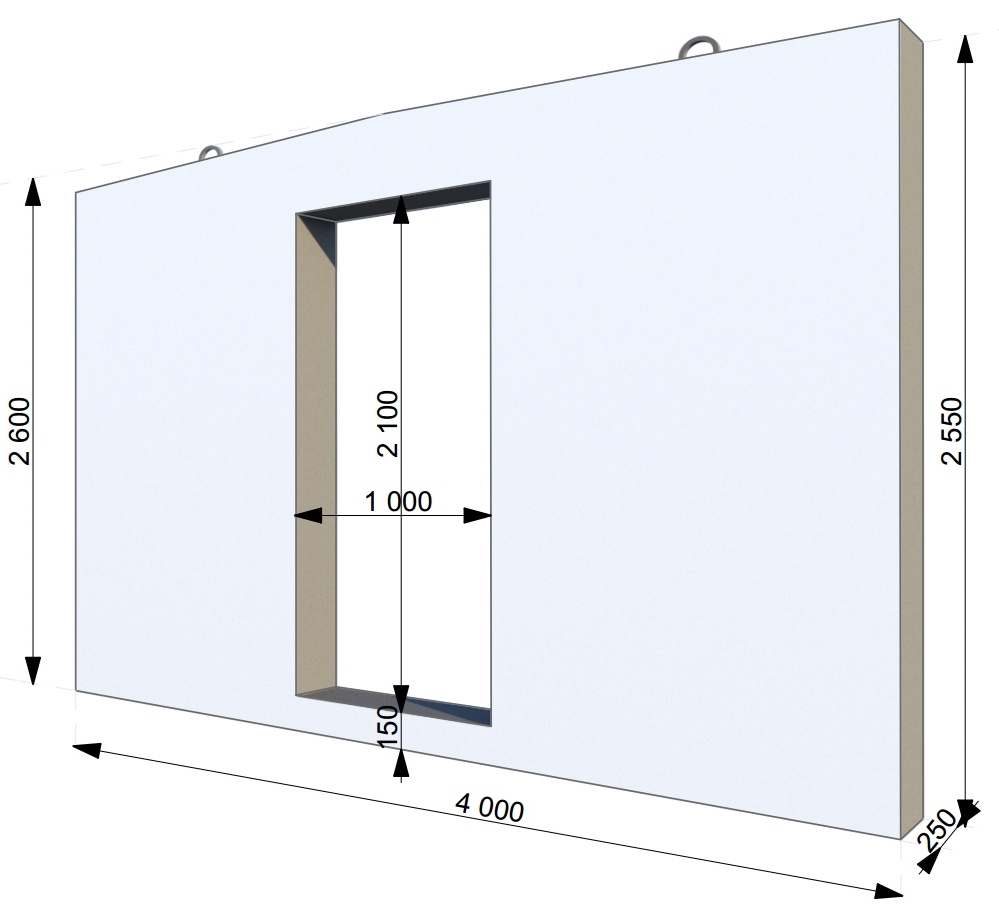

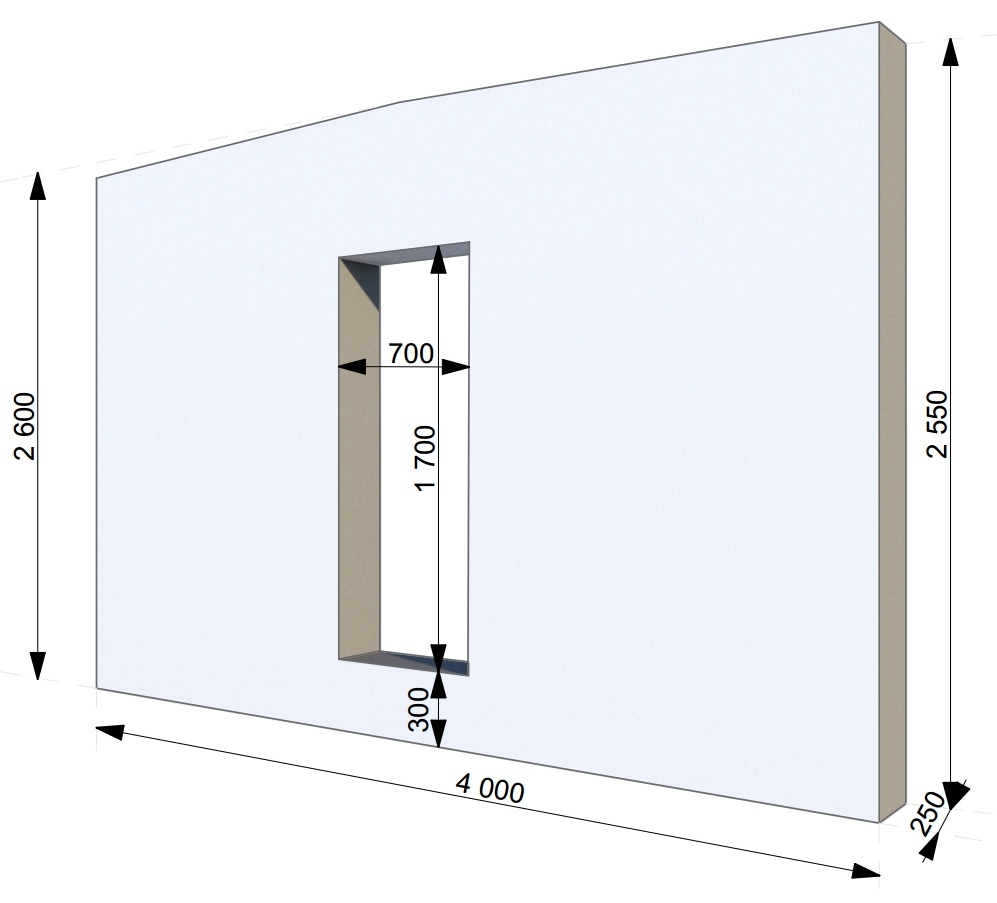

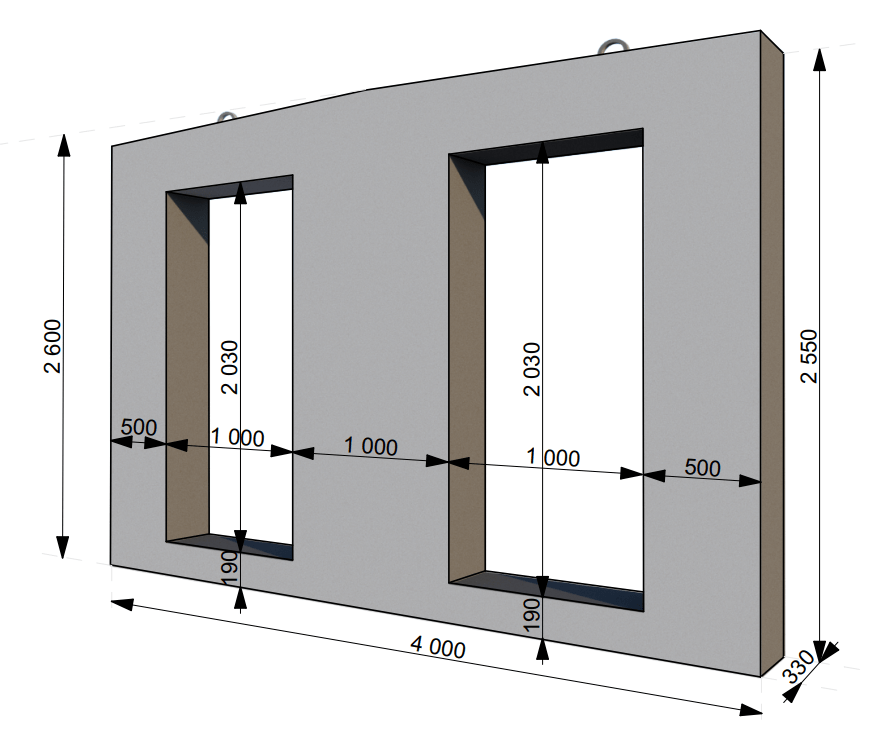

Variant 1

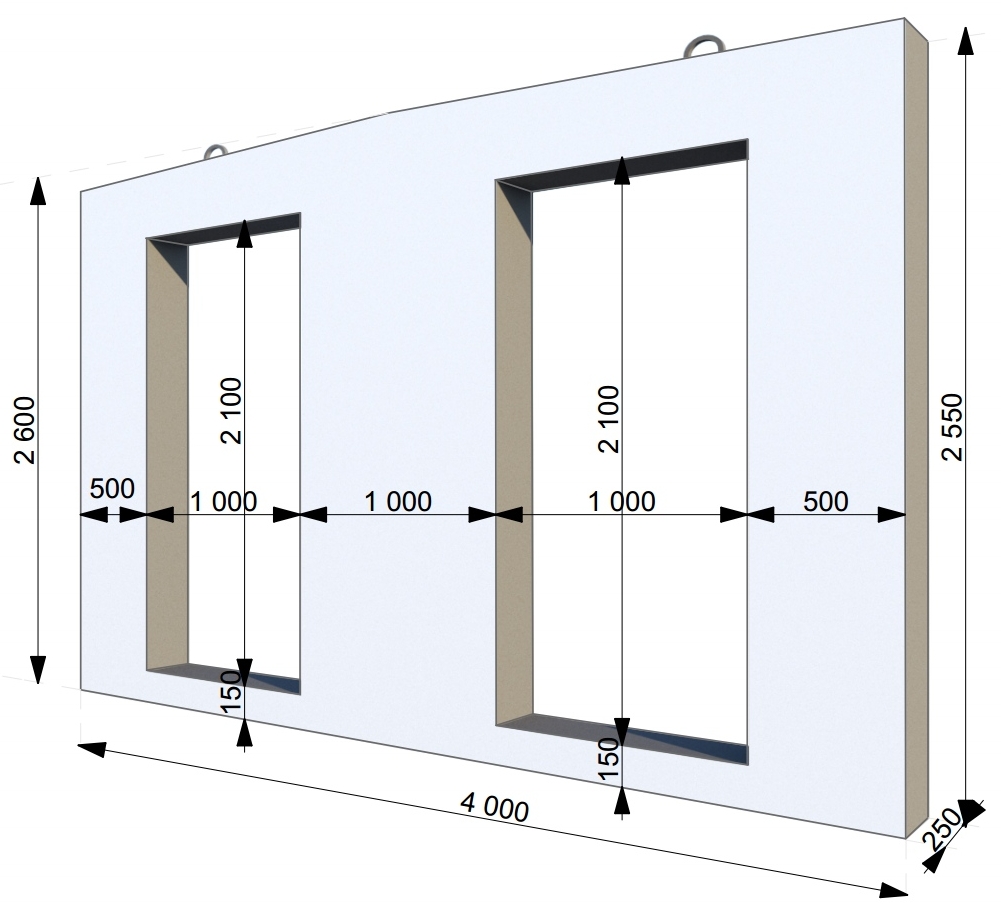

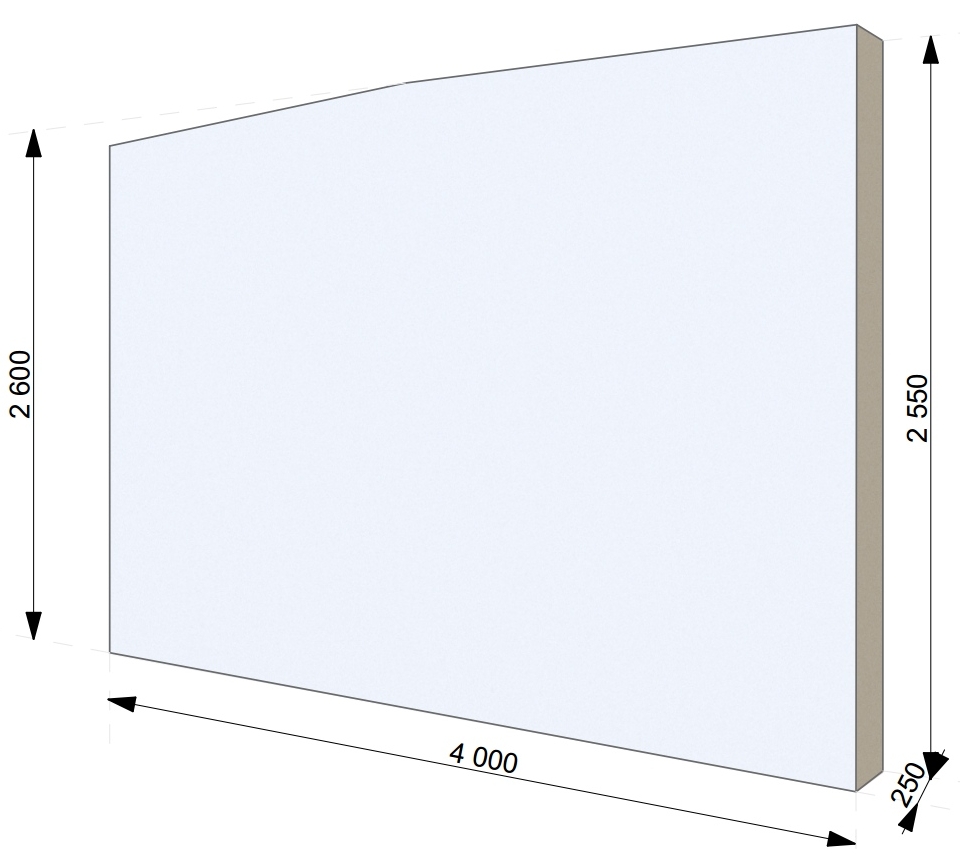

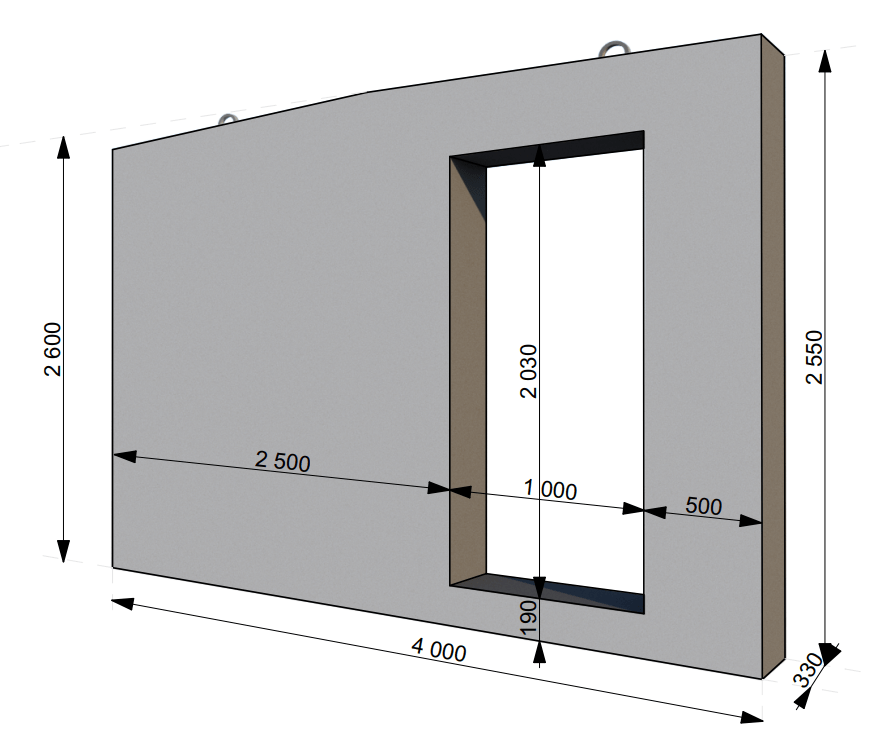

Variant 2

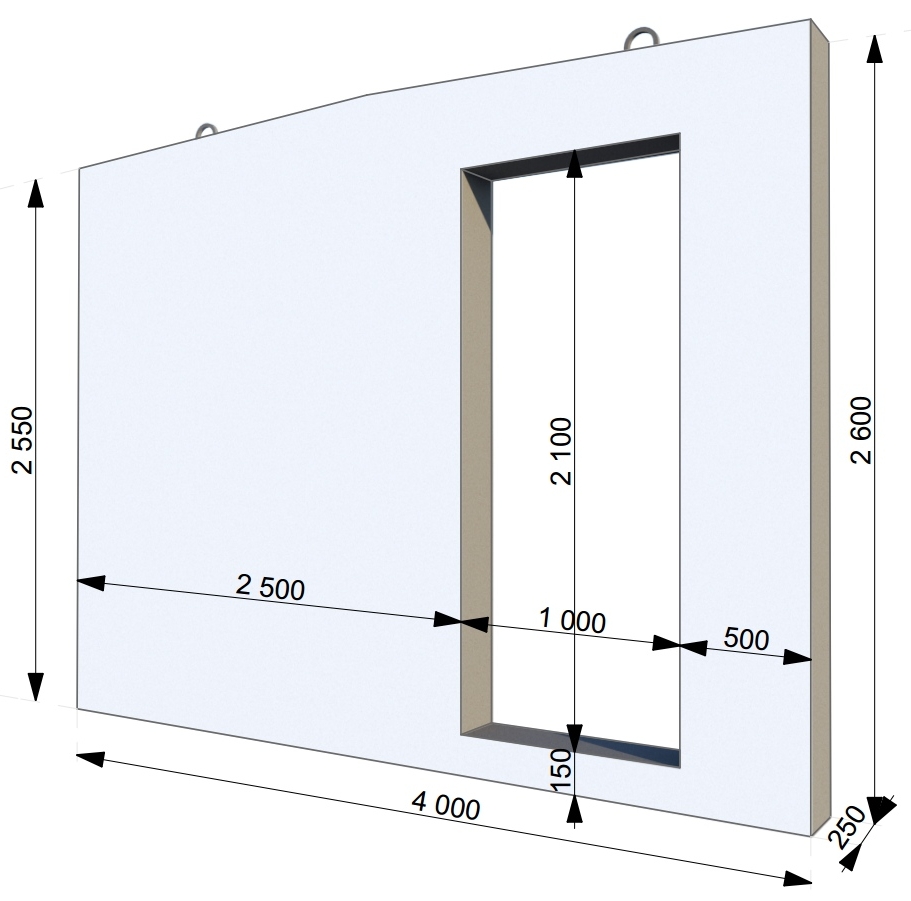

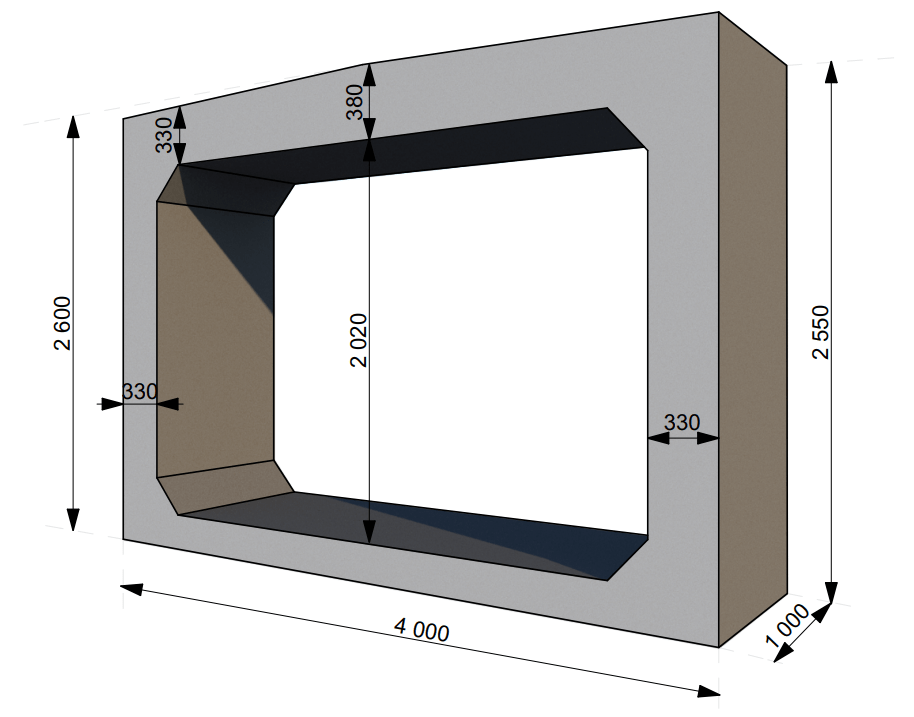

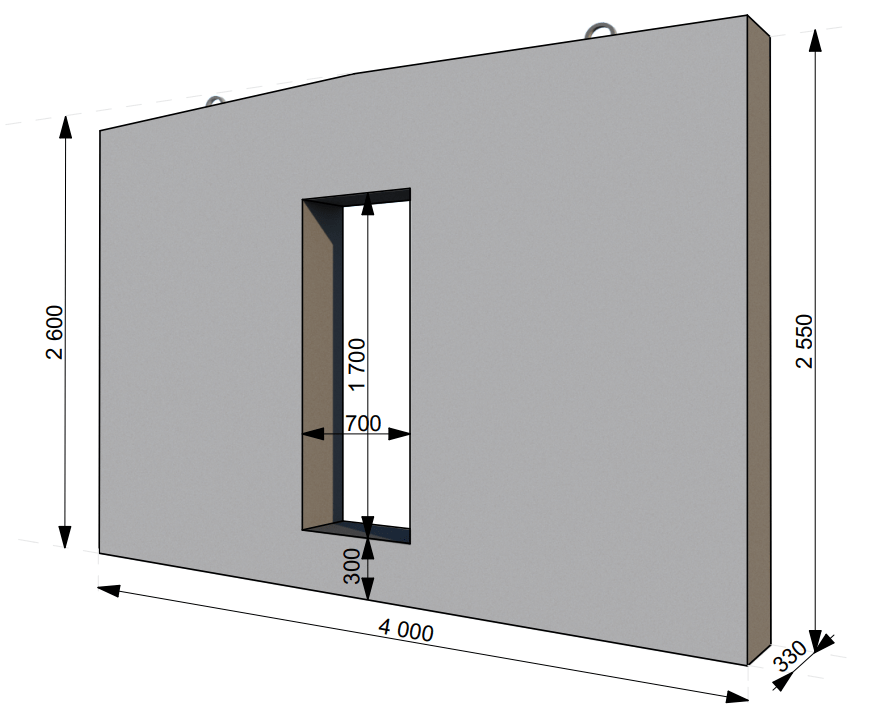

Variant 3

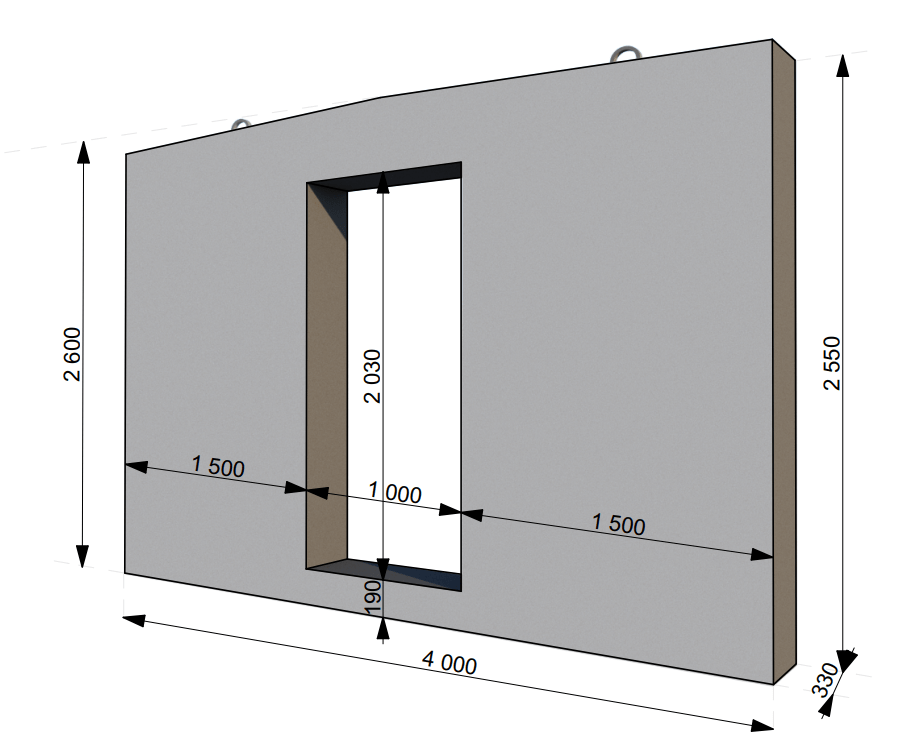

Variant 4

Variant 5

Variant 5

Private enterprise “YARO-BUD”

Identification code: 35620533

IBAN: UA853253650000000260060054046 in JSC “Kredobank”

Zaliznychna st., 45, Mykolaiv, Stryi district, Lviv region, 81600